The Autocirc ecosystem

The Autocirc ecosystem

As an insurer or workshop, you face growing pressure - stricter environmental requirements, rising costs, and customers who expect sustainable solutions. The Autocirc ecosystem is built to help you meet all three.

By reusing original auto parts instead of relying only on newly produced ones, you lower repair costs, reduce CO₂ emissions, and get warrantied quality parts you can trust. Together, we turn total loss vehicles into a circular model that benefits your business, your customers, and the planet.

We are joining sustainability and profitability on a new market dynamic driven by circular partnerships.

Today, the majority of all car repairs are carried out with newly produced parts. This is about to change. Increasingly strict environmental requirements and rising price sensitivity among companies and consumers are paving the way for reuse.

Our business model is circular by nature and helps insurers, workshops, and car owners reduce their costs and environmental impact – without compromising quality.

Circularity that delivers value

How can circular solutions lower costs, cut emissions, and secure reliable access to quality parts?

In our CEO interview, Hugues Delval explains how we are building Europe’s leading ecosystem for dismantling and reusing car parts - and why collaboration with insurers, workshops, and other partners is crucial. He also highlights the megatrends reshaping the industry - from stricter regulations to new technology – and how Autocirc turns these challenges into opportunities where sustainability, cost efficiency, and quality go hand in hand.

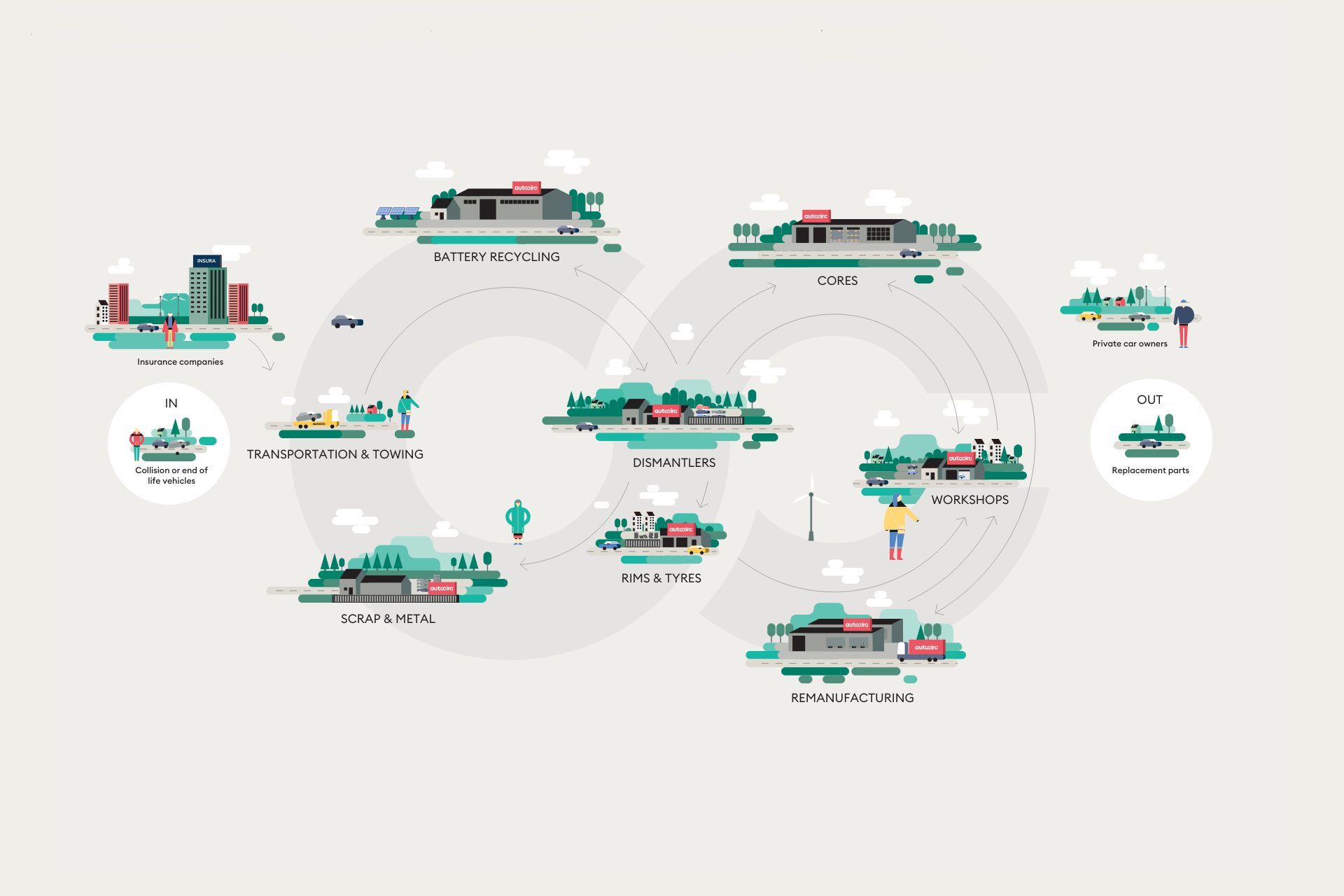

A business model without end

In our circular business model, there is no end - only new potential. Our eight business areas ensure that every auto part is put to the best possible use. Together, we increase the availability of sustainable high-quality spare parts and recycled materials.

For us, every car is the beginning of a new journey. Parts that can be reused go back on the road. Others are remanufactured, or recycled into raw materials for new products. Step by step, our business model makes sure as little as possible goes to waste.

Transport & towing

The first step in our circular business model is transporting vehicles to our dismantling facilities. We have several companies specializing in towing passenger cars and heavy vehicles.

Dismantling

Here, the vehicles are dismantled. A modern car consists of thousands of parts that we carefully evaluate and sort for reuse, remanufacturing, or recycling.

Rims & tyres

Our companies specializing in wheel refurbishment treat tires and rims so they can be reused. Alternatively, they are prepared for recycling and transformed into raw materials.

Battery reuse

We reuse batteries from electric cars. For example, as energy storage, where we connect several batteries together and install them in containers that can be moved to support local electricity grids.

Borås Bildemontering - expertise and innovation

With a strong reputation for high-quality dismantling, service capabilities, and environmental commitment, the Swedish dismantling company Borås Bildemontering helps us generate additional value across our circular ecosystem.

Caréco Molins - turns total loss to new value

Caréco Molins operates two strategic sites in France that forms an integral part of our European network. They are specialising in the field of reused vehicle parts, the sale of second-hand vehicles and the resale of new parts.

GBD - makes it possible to reuse 97% of a car

As Norway’s largest recipient of damaged vehicles from insurance firms, Grønvolds Bil-Demontering adds a stock of 63,000 auto parts to our supply chain, including an extensive range for electric vehicles.

Explore our companies

Transport and towing

Autonkuljetus Sjöberg OY (FI)

Bergen Bilhjelp AS (NO)

Bärgningstjänsten Sverige AB (SE)

Erikssons Bilbärgning AB (FI)

Hinaus Sjöberg OY (FI)

Hinaus Sjöberg Itä-Suomi OY (FI)

Konekuljetus Sjöberg OY (FI)

Redningsverket AS (NO)

Voss Bilbergning AS (NO)

Dismantling

Alingsås Bildelar AB (SE)

Autodemontering TT AB (SE)

Autopalsta OY (FI)

Auto Pièces SAS Louhans (FR)

Auto Pièces SAS Reims (FR)

Autoverwertung Kerstingjohänner GmbH (DE)

Beck Export Automobile (FR)

Bergen Bildemontering (NO)

Bildelslagret i Lidköping AB (SE)

Bildelslagret i Trollhättan AB (SE)

Borås Bildemontering AB (SE)

CAPO SAS Pontalier (FR)

Coram Auto SAS (FR)

Caréco Molins (FR)

Delehuset AS (NO)

Erikssons Bilåtervinning & Verkstad AB (FI)

Grønvolds Bil-Demontering AS (NO)

Jämtlands Bildemontering AB (SE)

Karlstads Bildemontering AB (SE)

Kungsåra Bildemontering AB (SE)

LB Teknik OY (FI)

Magnus Bildemontering AB (SE)

Norrbottens Bildemontering AB (SE)

Osamyynti AF OY (FI)

Redox Bildelar AB (SE)

Riihimäen Autoosat OY (FI)

RM Trucks OY (FI)

Rogaland Bildeler AS (NO)

Skjeberg Bilopphuggeri AS (NO)

Svensk Bilåtervinning AB (SE)

Svenssons Bildemontering AB (SE)

SVP Auto (PT)

Trondheim Bil-Demontering AS (NO)

Tröndelag Bildeler AS (NO)

Vimmerby Bildemontering AB (SE)

Växjö Bildemontering AB (SE)

Walters Bildelar AB (SE)

Ådalens Bildemontering AB (SE)

Östfolds Bildemontering AS (NO)

Remanufacturing

LBM Auto Parts AB (SE)

Nordic Motor Center AB (SE)

Rematrontech AB (SE)

Scandinavian Powertrain AB (SE)

Vaihteistokeskus OY (FI)

Battery Reuse

Autocirc Battery Recycling (FI)

Scrap & Metal

JM Gjenvinning AS (NO)

Rewinner AB (SE)

Circularity through four levels of value creation

A modern car consists of thousands of parts – each with a potential for future use. Our dismantlers are experts at disassembling vehicles, evaluating every component to maximise value creation. Within our circular business model, original auto parts contribute in four distinct ways.

Reuse

Reusing undamaged parts directly is the most sustainable and cost-effective option. We thoroughly inspect all parts to meet strict quality demands before reintroduction to the market.

Remanufacture

We restore high-demand damaged parts to as-new condition through remanufacturing. This process promotes sustainability by extending the life of critical components in the circular economy.

Repurpose

Auto parts unsuitable for reuse or remanufacturing can create new value in other ways. For example, electric vehicle batteries can be used to store energy, and contribute to society’s electricity supply.

Recycle

After reuse and remanufacturing options are exhausted, the remaining auto parts are recycled. This ensures that raw materials contribute to new vehicle parts or other products.