Clearing the way for sustainability

Clearing the way for sustainability

As the world’s population grows, so does the demand for transport, vehicles, and repairs. We believe the solution is not to limit people, but to offer sustainable alternatives. That’s why we drive the circular transition in the car parts industry.

We track and visualise emissions with precision, giving insurers, workshops, and other partners greater transparency and the ability to make informed choices that support their sustainability goals.

With clear data at hand, you gain a stronger basis for decisions – from cutting emissions across the value chain to showing measurable progress that builds trust with customers and stakeholders.

Behind every reused part is a team committed to making circularity work – for insurers, workshops, and car owners alike.

With our customer reporting, insurers and workshops get the insights they need to deliver on their own sustainability goals. Clear, reliable data makes it easier to track progress, identify areas for improvement, and share results with stakeholders.

Every reused part is backed by a dedicated team committed to making circularity work – for insurers, workshops, and car owners alike. In practice, this means you can demonstrate measurable impact, strengthen your sustainability profile, and build trust with both customers and regulators.

Sustainability with transparency and impact

How can data and transparency help reduce emissions, cut costs, and build trust? In our ESG & Quality interview, Hanna Wadsten explains how Autocirc is strengthening its sustainability work – from more precise emission tracking to customer reporting that makes progress visible.

She also shares how industry trends and partnerships, like the Circular Car project with RISE, are pushing the circular transition forward. The focus is clear: reducing carbon emissions, maximising reuse, and making sustainability measurable and actionable – for customers, partners, and the climate.

We work for lower climate impact.

Both the consumer and the environment pay a lower price when we reuse. According to figures from IVL Svenska Miljöinstitutet, reusing car parts for repairs reduces carbon dioxide emissions by 75% compared to using new ones.

We continuously invest in our ability to track, visualise, and analyse our sustainability efforts. This enables us to reduce our emissions and deliver high-quality reporting in line with complex regulations.

Our main priority is to keep lowering emissions and maximising the reuse of car parts. With new tools for data and reporting, we can follow our progress more closely – giving you greater transparency and a clearer basis for sustainable choices.

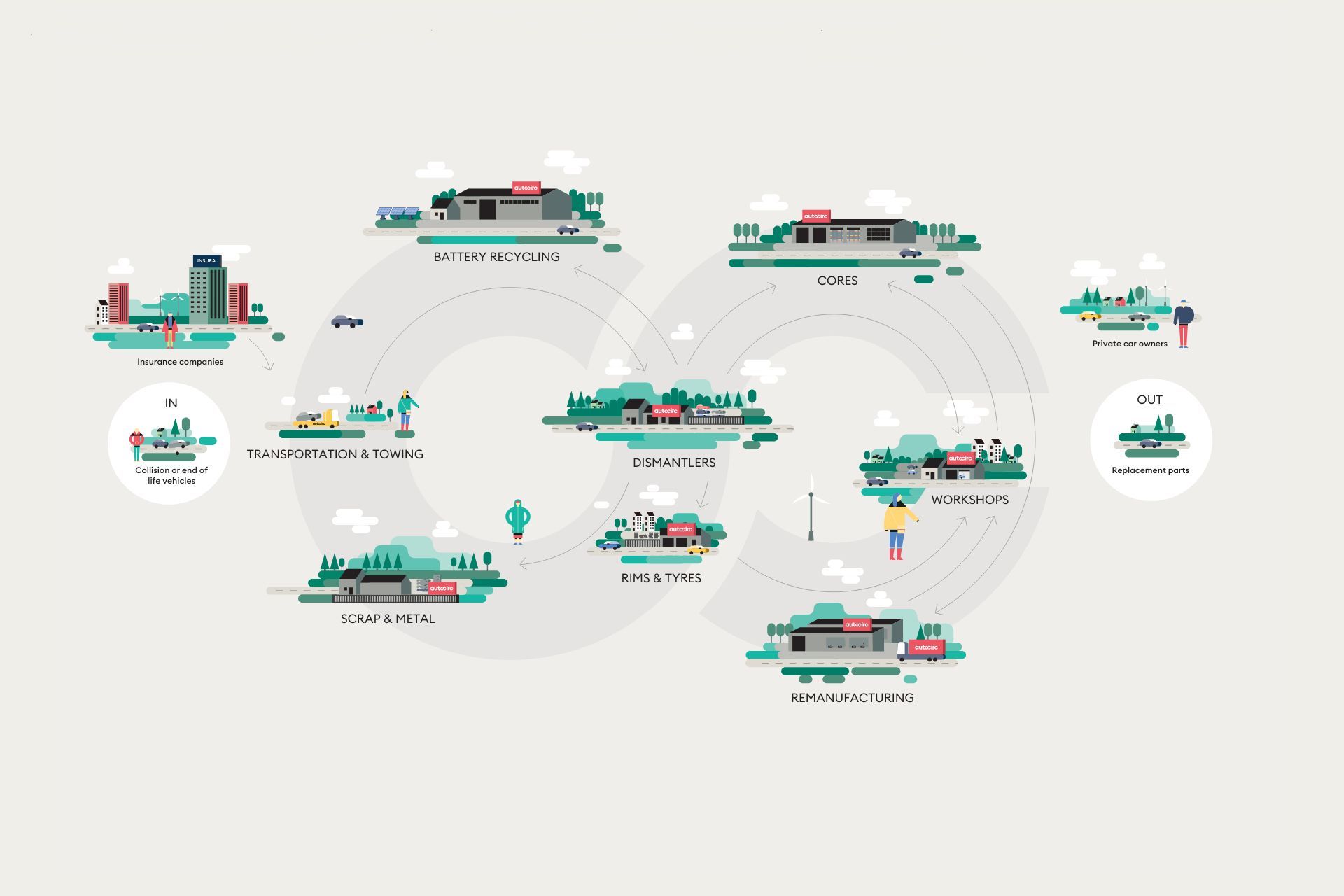

Be a part of our platform for circularity.

In our circular business model, there is no end – only new potential. Our eight business areas ensure that every auto part is put to the best possible use. Together, we increase the availability of sustainable high-quality spare parts and recycled materials.

Sustainability highlights 2024

The Circular Car

The pioneering Swedish research project 'The Circular Car' was launched, aiming to jointly accelerate the transition to a car fleet designed for circularity by 2045. Autocirc participates as one of several key stakeholders across the automotive value chain. The project is funded by Vinnova and coordinated by RISE.

Breakthrough in remanufacturing

Through the iReGear project, Autocirc´s Scandinavian Transmission Service AB (STS) achieved a sustainability milestone by integrating a remanufactured gearbox into Scania’s production line. The gearbox met all quality and performance standards for new parts, proving that remanufacturing is a truly sustainable alternative.

New data management platform

We introduced a new data platform to streamline ESG data management within the Autocirc Group. This initiative enhances our capacity to monitor and analyse sustainability metrics, ensuring precise and reliable reporting for a circular future – with a clear focus on reducing carbon emissions and maximising reuse.

A workplace where differences become strengths.

The idea of Autocirc is that our companies complement and strengthen each other to make a difference for the automotive industry at large. This also applies at the individual level. We are a modern employer who wants to take responsibility by providing fair conditions to our employees.

READ MORE ABOUT OUR POLICIES